Stand out on the shelf

3 & 6-inch cores

Choose the core size that works best for your brand and your machines.

film winding specification

Choose the direction you want your rollstock wound.

roll sizes

Max outer diameter can be based on imperial or metric measurement or impression count.

co-packer accommodations

Materials are converted based on co-packer needs, including unwind, seals and max outer diameter.

rollstock for brands of all sizes

Ideal for a wide variety of products — everything from granola bars to packaged snacks to single-serve sample packs — rollstock is most suited to brands looking to create pillow pouches, packets, sachets and lay flat pouches using their own pouch-making equipment.

Whether you’re an established brand getting ready to launch a new product to market, or a new brand looking to work with a co-packer to package your product, you can benefit from ePac’s low minimum orders, short runs, industry-best turnaround time (10 days for rollstock, 15 days for finished pouches), and on-demand ordering.

“Sometimes we have multiple SKUs under various brand families and we want to conduct a market test to see which package works best. Through ePac’s short run fulfillment, there is much less cost associated with backstock, parts and other wasted materials. We can run 2,000 instead of 20,000 and conduct A/B testing quickly and efficiently.”

— Trevor Parrick

Director of Technical Sales & Services, West Shore Foods LLC

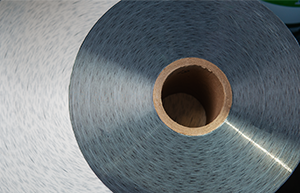

high-performance, high-quality rollstock

Our state-of-the-art digital printing technology makes it possible to deliver better rollstock with an incredibly fast turnaround all while using less energy and producing less waste than traditional printing methods.

Our finished rollstock runs on both vertical and horizontal FFS equipment and on both manual and fully automatic machinery. Our quality control measures ensure that each order, whether 10,000 or 1,000,000 impressions, is printed perfectly.

rollstock fAQs

What are the rollstock options?

Our rollstock options include the following:

- Ideal for pillow pouches, packets, and sachets

- Seal options:

- Fin Seal

- Lap Seal

- 76 & 152 mm cores

- Film winding specification

- High vapor barriers that block moisture, oxygen, and aroma from entering or exiting the package

- Transparent or clouded windows

- Metalised films

- Puncture and tear-resistant

- Available in a wide range of sizes

- Spot embellishments

We strive to provide solutions for each person. For custom requests, please contact our team here or by calling us at +44 1295 793793.

What are your film structures and material options?

We offer our customers a variety of materials and film structures including:

- Print Substrates PET, Metallised PET, PE, and BOPP

- Finishes available in:

- Traditional Matte

- Soft-touch Matte

- Gloss

- Metalised

- High-barrier and multi-layer sealant films

- Specialty laminate films

- Recyclable films

- Metalised PET and foil

- Freezer safe and Microwaveable options available

I am working with a co-packer. What accomodations can you make?

That’s great! We can assist with many different co-packer requests to efficiently convert your material including different seals, max outer diameter options, and unwind options.

Do you offer recyclable or compostable films?

We’re very proud to offer a recyclable PE pouch suitable for the UK’s On-Pack Recycling Label (OPRL) system and for RecycleNow Store Collection points, as well as a pouch using up to 30% post-consumer recycled resins.

What is your turnaround time on rollstock?

Rollstock will be produced in 10 business days, once your artwork has been approved.

Ready For A Quote?

We’re excited you’re considering ePac as your new flexible packaging provider. Use the button below to tell us about your project.

Additional Resources

Winter Packaging Ideas: Transform Your Products with Seasonal Designs

As the winter season begins, it’s time for brands to refresh their packaging and capture the spirit of the colder months. Whether you’re offering holiday-themed treats or cosy winter products, seasonal packaging can create a memorable experience and drive sales. In this post, we’re sharing some of our favourite winter packaging ideas to help your […]

Stick Pack Packaging: Is It Right for Your Brand?

When it comes to convenience, you can’t beat stick pack packaging. Whether you’re looking to create a sample package, or add single-serving size pouches to your product line, sticks packs are a unique way to package your products and attract new customers. Stick pack pouches are a type of flexible packaging characterized by their small […]

The Ultimate Flexible Packaging Guide: Benefits of Flexible Packaging, Different Types & Materials, Pricing To Look For

In today’s competitive consumer goods market, CPG companies are constantly seeking innovative ways to enhance their product packaging and stand out from the crowd. Flexible packaging has emerged as an innovative and popular way to stand out. In this guide we hope to provide a comprehensive overview of flexible packaging, including its benefits, different types, […]

7 Advantages of Digitally Printed Flexible Packaging

Regardless of the size of your company, digitally printed flexible packaging has a variety of benefits over conventional printing methods like offset, gravure, and flexographic. There are many differences between digital and conventional printing, and while traditional print is a great choice for many brands, there are several advantages to choosing digitally printed flexible packaging. […]

BRC and Food Grade Standards For Food Packaging

When you’re a U.K. company, your packaging does matter. Every company wants to score the vaulted A.A. rating from the British Retail Consortium (BRC), which assures packaging suppliers are compliant with the Global Food Safety Initiative (GFSI). The BRC certification is a food safety standard demonstrating a company’s commitment to industry best practices. A high […]

10 Direct-to-Consumer (D2C) Tips For Your Brand

If you’re a new CPG, pet food, or even a non-food brand selling a consumer product, you might be either thinking about selling directly to consumers, or you’re already doing it. In fact, the new generation of CPG brands – CPG 2.0 as we call them – are bypassing what is expected of traditional CPG […]

What Is a Co-Packer and Why You Should Use One

It’s time to take those brownie bites you’ve been selling at the local farmer’s market to the next level. While it’s been fun making a mess every weekend in the kitchen, meeting and greeting all these new customers, and slapping stickers on the brown paper bags, a major retailer has reached out and wants to […]

How To Choose the Right Thickness for Your Mylar Bags Depending on Your Product

When looking for the right kind of bag for your product, there are multiple details to consider. It’s not “just a bag” but, instead, the gateway of your product to the people. Some people don’t even know what a mylar bag is – it’s a bag made of polyethylene terephthalate, and mylar is just the […]

Pinole Blue: Revitalizing an Ancient Superfood with a Modern Twist

We’ve said it before, and we’ll repeat it – ePac gets to collaborate with some of the coolest companies. In this edition of our customer stories, we sat down with Kate, the co-founder at Pinole Blue got the inside scoop on what it was like to be featured on Shark Tank and how ePac has helped […]

Celebrating Everyday Heroes: Kettle Heroes’ Mosaic Packaging Initiative with ePac Flexible Packaging

At Kettle Heroes, the ethos of championing everyday heroes and uplifting core values of integrity, humility, and community service is more than just a mission—it’s a visible commitment. Partnering with ePac Flexible Packaging and the Pat Tillman Foundation, Kettle Heroes has harnessed the innovative mosaic printing technology to transform this ethos into a tangible experience […]

Unwrapping Joy: A Sweet Journey with Treat Kitchen

Masters of Delightful Confectionery? In the bustling world of food gifting, where every bite tells a story, Treat Kitchen stands out as a beacon of sweetness and sustainability. Founded in 2016, this dynamic company has been crafting delicious chocolates and sweets that transcend borders, reaching 21 countries overseas along with their beloved home in the […]

VB Kaffee’s Sustainable Packaging Upgrade

VB Kaffee, founded by Matthias, is a specialty coffee brand rooted in a passion for quality and sustainability. From humble beginnings as a coffee enthusiast experimenting with small batches, Matthias embarked on a journey to bring exceptional coffee to his community. Over the years, VB Kaffee has evolved into a reputable coffee supplier, focusing on […]